Commercial

- Office Building

The Republic Office Building – LEED

Size

Location

Owner

Client

The Republic is a 37-story, 1,426,221 GSF mixed-use office & retail tower with integrated parking garage. Command Commissioning is performing LEED Fundamental Verification & Commissioning, Enhanced Commissioning, Austin Energy Green Building Commissioning, and City of Austin Commissioning to achieve the sustainability goals of the owner and developer. This facility will tie into the City of Austin District Cooling Plant system and will include typical MEP systems and equipment as outlined below:

· Garage Exhaust & Make-Up Fans and Sensors

· CHW Pumps & Heat Exchanger System

· Boilers and Baseboard Heating System

· Air Handling Units & Outside Air Handline Units

· Electric Unit Heaters

· Building Exhaust & Makeup Fans

· Stair Pressurization Fans

· VAV & FPVAV Terminal Units

· DX Split Systems

· Misc FCUs for Elec/Tel/Garage Lobbies

· BMCS

· House Pump Skids & Sump Pumps/Sewage Ejectors

· Water Heater & Circulating Pump Combination

· Reclaimed Water System

· Fire Pump(s) & Controllers & Fire Alarm System

· Building Exterior Lighting System

· Emergency Generator

· Automatic Transfer Switches

· Balcony & Amenity Level Lighting Controls

· Level 1 Lighting & Controls & Garage Lighting Controls

Aviation

- Central Plant

HAS SCUP Cx

Size

Location

Owner

Client

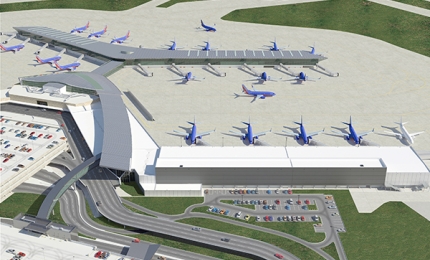

This project consisted of the installation of four new 1,100 Ton chillers in the existing satellite central utility plant (SCUP) at Hobby Airport in Houston, TX. Upon completion of the SCUP, the existing Central Utility Plant (CUP) was decommissioned and demolished. The new chillers, cooling towers, and pumps allowed for N+1 redundancy in the SCUP. The new chilled water system was configured as a variable primary system with one set of variable secondary pumps serving the FIS Terminal. A bypass around the FIS secondary pumps was constructed to allow the primary pumps to serve the FIS when differential pressures and load allow. Our team developed a Method of Procedure (MOP) for transitioning the chilled water systems from the existing plant to the new SCUP that would allow us to test the SCUP without impacting normal airport operations.

During the project, our team was able to pretest the CW system while the SCUP was isolated from the terminals, but we were unable to test the new chillers without load from the airport. CCLLC developed a MOP that allowed our team to test the new chillers with the loop opened to the terminals, in incremental steps, over the span of several days. This required careful planning, close coordination with airport operators, a well-staffed project team, and maximum efficiency on the part of our team to ensure everything was properly tested in the short windows of time we were given. Each night we would take the existing plant offline, open the loop to the SCUP, perform the procedures we had planned for that night, take the SCUP offline, isolate the SCUP from the airport, and put the existing CUP back into operation all between the hours of 10pm and 4am.

Aviation

- Airport Terminal

HAS ITRP – Mickey Leland International Terminal (MLIT)

Size

Location

Owner

Client

The George Bush Intercontinental Airport Terminal Redevelopment Program (ITRP) is the largest capital improvement program in the history of the Houston Airports and consists of three projects: Mickey Leland International Terminal (MLIT), Enabling Utilities Landside (EUL), and Federal Inspection Services (FIS) renovation and expansion projects. The MLIT project is comprised of multiple subphase projects – relief/refresh phase of the gates and gate areas in the existing terminal D area, C-D connector phase (long corridor that connects terminal D to the C-D Knuckle), C-D knuckle phase (renovation to the concessions area where the connectors to terminal C and terminal D meet), new D West Pier (construction of an all new terminal area housing new gates for international flights), and sterile corridor (long corridor that moves passengers from international flights through customs and border protection before allowing them access into the rest of the airport). The FIS project will take the terminal processing functions for the international flights, currently located inside terminal D, and relocate it into a new expansion on the existing FIS, which also includes the renovation of much of the existing FIS. The EUL project is a new water production plant site for domestic water and sewer utilities for terminal D. CCLLC led a Cx team, including subconsultants, responsible for MEP, F/A, Access Control, BECx, and TAB Verification. We provided technical Cx services per IECC 2015, LEED v4.1 pre-requisite on energy consuming mechanical, electrical, and plumbing systems and Enhanced Monitoring-Based Cx.

Aviation

- Airport Terminal

HAS ITRP – FIS

Size

Location

Owner

Client

The George Bush Intercontinental Airport Terminal Redevelopment Program (ITRP) is the largest capital improvement program in the history of the Houston Airports and consists of three projects: Mickey Leland International Terminal (MLIT), Enabling Utilities Landside (EUL), and Federal Inspection Services (FIS) renovation and expansion projects. The MLIT project is comprised of multiple subphase projects – relief/refresh phase of the gates and gate areas in the existing terminal D area, C-D connector phase (long corridor that connects terminal D to the C-D Knuckle), C-D knuckle phase (renovation to the concessions area where the connectors to terminal C and terminal D meet), new D West Pier (construction of an all new terminal area housing new gates for international flights), and sterile corridor (long corridor that moves passengers from international flights through customs and border protection before allowing them access into the rest of the airport). The FIS project will take the terminal processing functions for the international flights, currently located inside terminal D, and relocate it into a new expansion on the existing FIS, which also includes the renovation of much of the existing FIS. The EUL project is a new water production plant site for domestic water and sewer utilities for terminal D. CCLLC led a Cx team, including subconsultants, responsible for MEP, F/A, Access Control, BECx, and TAB Verification. We provided technical Cx services per IECC 2015, LEED v4.1 pre-requisite on energy consuming mechanical, electrical, and plumbing systems and Enhanced Monitoring-Based Cx.

Systems and Equipment included:

MEP Cx: HVAC; Plumbing; Building Automation Systems; Lighting Control Systems

Specialty Systems: Electrical Power Generation; Existing Central Utility Plant;

Subcontractor Systems: Building Enclosure Systems; Security Access Controls; Fire/Life Safety

Education K12

- Classroom

NISD Pike Middle School Replacement

Size

Location

Owner

Client

Northwest ISD is building a new Pike Middle School to help with the needs of the growing district. The replacement school will be located on the land just south of the current campus -on the site of the old One Horse Farm. The new middle school is going to be roughly 219,500 SF and is scheduled to open in the fall of 2024.

Education K12

- Classroom

NISD NHS Additions & Renovations

Size

Location

Owner

Client

Renovations and expansions of Northwest High school funded by the 2023 bond to be completed for the fall 2025 school year. Some of the improvements include: Roof Replacement, Replace Greenhouse, Additional Seating in Auditorium, Enlarged Cafeteria and Kitchen, LED Lighting for Athletics, Restroom Improvements at Tennis Courts, Turf Replacement at Sub-Varsity Field, and Additional Bleachers at Sub-Varsity Field, Baseball Field and Softball Field.