Aviation

- Mission Critical/Data Center

EFD ATCT New Control Tower

Size

Location

Owner

Client

CCLLC was retained by Shelco to provide construction phase commissioning services of the new Ellington Airport Air Traffic Control Tower. The Tower is approximately 1,300 SQFT and 160 feet tall. It controls air traffic for civilian, commercial, military/homeland security, and NASA training operations. An accompanying utility building houses an emergency generator, fire pump, boilers, and HVAC pumps, and a utility yard includes fire water storage, chillers, a transformer, and a fuel tank. Our scope of work included developing specifications for commissioning, developing pre-functional checklists, and functional performance testing. Our team reviewed submittals related to the mechanical systems, reviewed O&M manuals for completeness, oversaw training for equipment and systems, documented and tracked all deficiencies and issues, and verified installation and startup of equipment. CCLLC prepared reports, field observations, issues and test results in a final report to Houston Airport Systems for acceptance of the project. Systems and Equipment included:

MEP Cx: HVAC; Plumbing; Building Automation Systems; Lighting Control Systems

Specialty Systems: Electrical Power Generation; Central Utility Plant;

•Mechanical: Chilled Water System, Heating Water System, Air Handling Equipment, Test and Balance Verification, BAS, Fuel Oil Systems.

•Plumbing: Domestic Water System, Gas Piping, Domestic Water Booster Pumps, Domestic Water Heater.

•Electrical: Switchboard, Distribution Panels, Breakers, LV Transformers, Emergency Power Generator, Bypass ATS, Fire Pump ATS, Grounding System, Lightning Protection, Building Lighting Controls, Roller Window Shades, Taxiway Lighting.

•Life and Safety Systems: Fire Alarm System, Pre-Action System, Fire Pumps, Security/CCTV

•Other: Elevator and Building Envelope

Aviation

- Central Plant

HAS SCUP Cx

Size

Location

Owner

Client

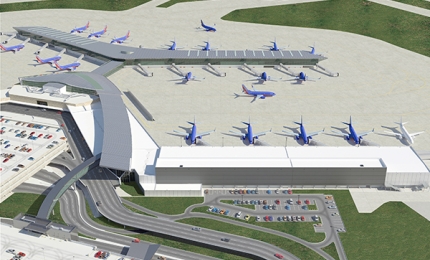

This project consisted of the installation of four new 1,100 Ton chillers in the existing satellite central utility plant (SCUP) at Hobby Airport in Houston, TX. Upon completion of the SCUP, the existing Central Utility Plant (CUP) was decommissioned and demolished. The new chillers, cooling towers, and pumps allowed for N+1 redundancy in the SCUP. The new chilled water system was configured as a variable primary system with one set of variable secondary pumps serving the FIS Terminal. A bypass around the FIS secondary pumps was constructed to allow the primary pumps to serve the FIS when differential pressures and load allow. Our team developed a Method of Procedure (MOP) for transitioning the chilled water systems from the existing plant to the new SCUP that would allow us to test the SCUP without impacting normal airport operations.

During the project, our team was able to pretest the CW system while the SCUP was isolated from the terminals, but we were unable to test the new chillers without load from the airport. CCLLC developed a MOP that allowed our team to test the new chillers with the loop opened to the terminals, in incremental steps, over the span of several days. This required careful planning, close coordination with airport operators, a well-staffed project team, and maximum efficiency on the part of our team to ensure everything was properly tested in the short windows of time we were given. Each night we would take the existing plant offline, open the loop to the SCUP, perform the procedures we had planned for that night, take the SCUP offline, isolate the SCUP from the airport, and put the existing CUP back into operation all between the hours of 10pm and 4am.

Aviation

- Airport Terminal

HAS ITRP – Mickey Leland International Terminal (MLIT)

Size

Location

Owner

Client

The George Bush Intercontinental Airport Terminal Redevelopment Program (ITRP) is the largest capital improvement program in the history of the Houston Airports and consists of three projects: Mickey Leland International Terminal (MLIT), Enabling Utilities Landside (EUL), and Federal Inspection Services (FIS) renovation and expansion projects. The MLIT project is comprised of multiple subphase projects – relief/refresh phase of the gates and gate areas in the existing terminal D area, C-D connector phase (long corridor that connects terminal D to the C-D Knuckle), C-D knuckle phase (renovation to the concessions area where the connectors to terminal C and terminal D meet), new D West Pier (construction of an all new terminal area housing new gates for international flights), and sterile corridor (long corridor that moves passengers from international flights through customs and border protection before allowing them access into the rest of the airport). The FIS project will take the terminal processing functions for the international flights, currently located inside terminal D, and relocate it into a new expansion on the existing FIS, which also includes the renovation of much of the existing FIS. The EUL project is a new water production plant site for domestic water and sewer utilities for terminal D. CCLLC led a Cx team, including subconsultants, responsible for MEP, F/A, Access Control, BECx, and TAB Verification. We provided technical Cx services per IECC 2015, LEED v4.1 pre-requisite on energy consuming mechanical, electrical, and plumbing systems and Enhanced Monitoring-Based Cx.

Aviation

- Airport Terminal

HAS ITRP – FIS

Size

Location

Owner

Client

The George Bush Intercontinental Airport Terminal Redevelopment Program (ITRP) is the largest capital improvement program in the history of the Houston Airports and consists of three projects: Mickey Leland International Terminal (MLIT), Enabling Utilities Landside (EUL), and Federal Inspection Services (FIS) renovation and expansion projects. The MLIT project is comprised of multiple subphase projects – relief/refresh phase of the gates and gate areas in the existing terminal D area, C-D connector phase (long corridor that connects terminal D to the C-D Knuckle), C-D knuckle phase (renovation to the concessions area where the connectors to terminal C and terminal D meet), new D West Pier (construction of an all new terminal area housing new gates for international flights), and sterile corridor (long corridor that moves passengers from international flights through customs and border protection before allowing them access into the rest of the airport). The FIS project will take the terminal processing functions for the international flights, currently located inside terminal D, and relocate it into a new expansion on the existing FIS, which also includes the renovation of much of the existing FIS. The EUL project is a new water production plant site for domestic water and sewer utilities for terminal D. CCLLC led a Cx team, including subconsultants, responsible for MEP, F/A, Access Control, BECx, and TAB Verification. We provided technical Cx services per IECC 2015, LEED v4.1 pre-requisite on energy consuming mechanical, electrical, and plumbing systems and Enhanced Monitoring-Based Cx.

Systems and Equipment included:

MEP Cx: HVAC; Plumbing; Building Automation Systems; Lighting Control Systems

Specialty Systems: Electrical Power Generation; Existing Central Utility Plant;

Subcontractor Systems: Building Enclosure Systems; Security Access Controls; Fire/Life Safety

Aviation

- Central Plant

Hobby Airport Satellite Central Utility Plant

Location

This project consisted of the installation of four new 1,100 Ton chillers in the existing satellite central utility plant (SCUP) at Hobby Airport in Houston, TX. Upon completion of the SCUP, the existing Central Utility Plant (CUP) was decommissioned and demolished. The new chillers, cooling towers, and pumps allowed for N+1 redundancy in the SCUP. The new chilled water system was configured as a variable primary system with one set of variable secondary pumps serving the FIS Terminal. A bypass around the FIS secondary pumps was constructed to allow the primary pumps to serve the FIS when differential pressures and load allow. Our team developed a Method of Procedure (MOP) for transitioning the chilled water systems from the existing plant to the new SCUP that would allow us to test the SCUP without impacting normal airport operations.

Commercial

- Office Building

The Republic Office Building – LEED

Size

Location

Owner

Client

The Republic is a 37-story, 1,426,221 GSF mixed-use office & retail tower with integrated parking garage. Command Commissioning is performing LEED Fundamental Verification & Commissioning, Enhanced Commissioning, Austin Energy Green Building Commissioning, and City of Austin Commissioning to achieve the sustainability goals of the owner and developer. This facility will tie into the City of Austin District Cooling Plant system and will include typical MEP systems and equipment as outlined below:

· Garage Exhaust & Make-Up Fans and Sensors

· CHW Pumps & Heat Exchanger System

· Boilers and Baseboard Heating System

· Air Handling Units & Outside Air Handline Units

· Electric Unit Heaters

· Building Exhaust & Makeup Fans

· Stair Pressurization Fans

· VAV & FPVAV Terminal Units

· DX Split Systems

· Misc FCUs for Elec/Tel/Garage Lobbies

· BMCS

· House Pump Skids & Sump Pumps/Sewage Ejectors

· Water Heater & Circulating Pump Combination

· Reclaimed Water System

· Fire Pump(s) & Controllers & Fire Alarm System

· Building Exterior Lighting System

· Emergency Generator

· Automatic Transfer Switches

· Balcony & Amenity Level Lighting Controls

· Level 1 Lighting & Controls & Garage Lighting Controls

Commercial

- Office

Frost Tower, San Antonio

Size

Location

Owner

Client

Frost Bank, the largest Texas-based bank, wanted a new modern headquarters that would be an iconic addition to the San Antonio skyline. The 460,000 SQFT, Class AA+ office building includes ground floor retail and restaurants, a fitness center, destination dispatch elevators, and tenant lounge featuring an exhibition kitchen. The tower is located along the San Pedro Creek Cultural Park to the east and a new green space to the west. The 23-story building also includes a six level above-grade parking garage.

Command Commissioning provided LEED Fundamental and Enhanced commissioning services for the tower which includes the energy consuming systems. Equipment commissioned includes water cooled chillers, cooling towers, pumps, lighting controls, booster pumps, water heaters, and the building management and control system. Our team verified that the equipment and systems were installed and calibrated to perform according to the OPR and BOD by physically witnessing the functional testing. Systems commissioned include HVAC, lighting controls, and domestic hot water.

Commercial

- Office

Chandler Viridian Office Building

Size

Location

Owner

Client

The Offices at Chandler Viridian is a six-story 250,000 SQFT office building featuring an expansive, open floorplan with 10-foot tall ceiling, a lounge, and large courtyard. The office building is the capstone of a larger, 25-acre development that includes a hotel, luxury apartments, retail, and the Chandler Fashion Center Mall. Our scope of work includes Fundamental and Enhanced commissioning as defined by the USGBC for LEED criteria. Systems commissioned include: all mechanical systems as they relate to HVAC, fuel oil, fire suppression, building management and controls, lighting, and electrical systems. Our team verified that the equipment and systems were installed and calibrated to perform according to the OPR and BOD by physically witnessing the functional testing.

Commercial

- Office

Victory Center

Size

Location

Owner

Client

One Victory Park is an 18 story, 450,000 SQFT office building in Dallas that serves as the front of Victory Park. The building serves as the office component to the Victory Park revitalization plan. The building sits immediately adjacent to the American Airlines Center (Home of the Dallas Mavericks and Dallas Stars) and the W Hotel. The facility features high-end office space, flexible building mechanical systems, high-efficiency floor plates, and ground floor retail space. We provided the LEED Fundamental and Enhanced Core and Shell commissioning. The project achieved LEED Silver certification. Our team verified that the project’s energy-related systems were installed and calibrated to perform according to the OPR and BOD by physically witnessing the functional testing.

Commercial

- Office

Transbay Tower

Size

Location

Salesforce Tower is the tallest tower in San Francisco, joining the Golden Gate Bridge and Transamerica Building in the iconic skyline. The high-rise building stands at 1,070 feet tall and 61-stories. The glass and metal accents on the exterior taper to accentuate the curved features of the building. The building is a novel approach to public-private collaboration and sustainability. Command Commissioning provided Fundamental and Enhanced LEED commissioning for this facility and commissioned the following equipment: chillers, cooling towers, boilers, heat exchangers, HVAC pumps, VFD’s, tripath AHU’s, VAV’s, DX split air conditioning units, fan/blower coil units, garage supply and exhaust, exhaust fans, transfer fans, building management & controls, lighting controls, and 600 volt feeders. Salesforce Tower connects directly to the transit center below grade and is built adjacent to a 5.4 acre public park. Sustainability features include the use of full outside air economizer ventilation systems, floor-by-floor air intake, under-floor air distribution, integrated metal sunshades, high-performance glass, floor-to-ceiling windows, and comprehensive water recycling systems.

Education (Higher)

- Classrooms

Norris Renovation Project

Size

Location

Owner

Client

The Norris Renovation Project consisted of the renovation of the Norris Technical Building, built in 1970 and now renamed in honor of Clarence W. Norris Sr, announced at the topping out ceremony in January of 2020. The scope consisted of the renovation of 70,000 SF of the 4-story student education center with study rooms, teaching labs, administrative areas, testing rooms, and classrooms. The newly renovated facility will house the Reading and English departments, IT department, as well as learning, reading, writing, and tutoring labs throughout the building.

Education (Higher)

- Multi-Purpose

SPC Hospitality and Culinary Arts

Size

Location

Owner

Client

The project consisted of the construction of a new four story, 60,000 SF Culinary and Hospitality Education Facility. The final building contained seven kitchens, two of which are full production kitchens serving food to the public in an adjoining dining area. The building also contains several hospitality training spaces, and the look and feel of the building is intended to emulate the working environment of commercial kitchens and hospitality facilities.

Education (Higher)

- Office

NVC Welcome Center Building

Size

Location

Owner

Client

The facility is meant to be a state-of-the-art Student Success building that will accommodate student services through innovative technologies to include: virtual way-finding, collaborative spaces, automated processing systems and a connecting four-story parking garage. The modern facility is approximately 50,000 SF with offices for: Welcome & Admissions, Advising, Testing, Financial Aid, Business Services, Veteran’s Affairs, Counseling, Services to Students with Disabilities

Education (Higher)

- Classrooms

Del Mar – SC STEM

Size

Location

Owner

Client

As part of a Texas Interlocal Purchasing System (TIPS) Agreement, Command Commissioning has been contracted to provide services to Del Mar College for multiple projects funded under a $139-million capital improvements bond program. CCLLC has been contracted to provide commissioning services for 4 projects to date.

Southside Campus – STEM Building

New four story, 100,665 SF structure designed to house administrative offices, classrooms, computer labs, shops, chemistry labs, and support spaces

The commissioning duties, tasks, and activities, include: the coordination of resources to support campus construction outside of the local region including: Meetings, Staffing, Scheduling, Travel, Leading Cx Kick-off meetings, Design reviews, Submittal reviews, Development and execution of PFCs/FPTs, Verification and testing of the BAS system

Education (Higher)

- Classrooms

Del Mar – SC Central Plant

Size

Location

Owner

Client

As part of a Texas Interlocal Purchasing System (TIPS) Agreement, Command Commissioning has been contracted to provide services to Del Mar College for multiple projects funded under a $139-million capital improvements bond program. CCLLC has been contracted to provide commissioning services for 4 projects to date.

Southside Campus – Central Plant.

New single story, 8,631 SF structure designed to support a Central Utility Plant for Del Mar College’s new Southside Campus. The initial deployment of equipment in the central plant is anticipated to be three (3) water-cooled chillers, three (3) cooling towers, three (3) natural gas fired boilers and associated pumps and controls. The commissioning duties, tasks, and activities, include: the coordination of resources to support campus construction outside of the local region including: Meetings, Staffing, Scheduling, Travel, Leading Cx Kick-off meetings, Design reviews, Submittal reviews, Development and execution of PFCs/FPTs, Verification and testing of the BAS system

Education (Higher)

- Office

Tarleton State Gough Hall Reno

Size

Location

Owner

Client

CCLLC was contacted by Tarleton State University (TSU) and SSC Services after the design was complete to perform commissioning services. After reviewing the construction drawings and specifications it was noted the project consisted of the remodel of an existing dormitory into an administrative building housing Employee Services and the Center for Education Excellence. Construction included the removal of the existing mechanical, electrical, and plumbing infrastructure and installation of new variable refrigerant flow air conditioners, fans, water heater, lighting system, and controls. The commissioning effort included testing the energy consuming systems in accordance with the 2015 International Energy Conservation Code.

Education (Higher)

- Laboratory/Research

Vernon Agrilife Research Center

Size

Location

The project consists of miscellaneous repairs to the building and storage facilities at the Agrilife Research and Extension Center in Vernon, Texas. The facilities were damaged in a severe tornado and thunderstorm that directly hit the center on May 4, 2022. There are two main entities at the Vernon Center, the Research and Extension main Facilities and the Foundation Seed facilities. The main facility is comprised of the main center that houses Research and Extension administrators, laboratories, various offices, and public auditorium. Additionally, there are two buildings that contain major agricultural equipment, a chemical storage facility, plant & soil head house and three greenhouses. The main headquarters facility had at least 60% of its roof membrane and all HVAC equipment blown off the roof and destroyed by the tornado. In total, eleven enclosed structures comprising over 68,000 square feet require some sort of system rework – from complete replacement to simple repairs.

Education K12

- Classrooms

Schluter Elementary School

Size

Location

Owner

Client

Our team was responsible for construction phase commissioning of the MEP Systems that support the Elementary Schools new ‘G’ and ‘H’ areas. The commissioning process for this project including developing a commissioning plan with specific functional performance tests, onsite walkthroughs and inspections, documentation review, development and maintenance of a commissioning issues logs, and prepare a final report

Education K12

- Classrooms

Berkshire Elementary School #20

Size

Location

Owner

Client

The elementary school was designed to be an approximately 100,910 SQFT, two-story school building.

CCLLC was retained by NISD to provide commissioning services for the new building. Our team was responsible for: Preliminary Commissioning Plan, Final Commissioning Plan, Issues Log with appropriate updates, Preliminary Commissioning Report, Final Commissioning Report, Review of Operations Manual and Updated Final Commissioning Report after off season testing.

Education K12

- Classrooms

Le Tara Middle School #7 Previously known as Worthington Middle School

Size

Location

Owner

Client

CCLLC is providing commissioning services in accordance with International Energy Conservation Code (IECC) 2015 and Division 01, 22, 23, and 26 commissioning specifications. Our services include creating a Preliminary Commissioning Plan, Final Commissioning Plan, Issues Log with appropriate updates, Preliminary Commissioning Report, Final Commissioning Report, Review of Operations Manual, and Updated Final Commissioning Report after off season testing for mechanical, electrical, and plumbing services.

Education K12

- Classroom

NISD Pike Middle School Replacement

Size

Location

Owner

Client

Northwest ISD is building a new Pike Middle School to help with the needs of the growing district. The replacement school will be located on the land just south of the current campus -on the site of the old One Horse Farm. The new middle school is going to be roughly 219,500 SF and is scheduled to open in the fall of 2024.

Education K12

- Classroom

NISD NHS Additions & Renovations

Size

Location

Owner

Client

Renovations and expansions of Northwest High school funded by the 2023 bond to be completed for the fall 2025 school year. Some of the improvements include: Roof Replacement, Replace Greenhouse, Additional Seating in Auditorium, Enlarged Cafeteria and Kitchen, LED Lighting for Athletics, Restroom Improvements at Tennis Courts, Turf Replacement at Sub-Varsity Field, and Additional Bleachers at Sub-Varsity Field, Baseball Field and Softball Field.

Education K12

- Classrooms

KISD East Ward/West Ward Elementary

Size

Location

Owner

Client

New $44,000,000 East Ward & West Ward Elementary Consolidation. The new elementary school on the existing East Ward site will serve grades PreK—5th with a capacity of 1,050 students and includes 63 classrooms, 3 art/science rooms, 3 music rooms and 3 computer labs. as well as a 5,000 SQFT gym, 6,000 SQFT library, 11,250 SQFT dining and kitchen, 8,740 SQFT administrative space, and 2,135 SQFT custodial area.

CCLLC was selected to execute commissioning services for the district under their IDIQ solicitation and is comfortable presenting comprehensive capabilities and services provided by our firm that can meet the programming requirements for our customers without having specific project scopes in mind. The commissioning performance requirements for the project are to provide 2018 IECC Code Cx but we are also providing commissioning to meet the Whole Building Cx specifications that are included in the design record documents for each project. The commissioning duties, tasks, and activities, include the coordination of resources to support campus construction outside of the local region including: Meetings, Staffing, Scheduling, Travel, Leading Cx Kick-off meetings, Design Phase Cx Reviews, Submittal Reviews, Development and execution of PFCs/FPTs, Verification and testing of the BAS system, Compilation of O&Ms, Training Materials, and Systems Manual

Government

- Military Base

Ft. Gordon AAFES Shopping Center Georgia

Size

Location

Owner

Client

The Ft. Gordon shopping center project included the remodel of 91,000 SQFT and 83,000 SQFT addition. The facility includes retail sales, administrative, food service, mall, commodities, MPA, MCSS, and pharmacy space. The building is designed and was commissioned to receive LEED Silver Certification.

Command Commissioning produced a commissioning plan and schedule which included all areas of work, components, equipment, and systems, to be commissioned. A Cx kick-off meeting with key stakeholders was held explaining personnel responsibilities, daily reporting requirements, points of contact and coordination of all efforts to execute the contract.

Government

- Military Base

Exchange San Antonio – Fort Sam Houston

Size

Location

Owner

Client

New Exchange Shopping Center approximately 206,500 SQFT in a single building which includes an Exchange Store, Outdoor Living, Mall and Food Court. The project also includes the construction of new driveways, parking lots, truck service yards and the demolition of separate existing PX, Burger King and Pharmacy buildings. Command Commissioning evaluated the design, performance, and operation of the Project’s MEP systems from construction through to occupancy. Our team provided LEED fundamental and enhanced commissioning, the project is pursuing LEED Silver certification.

Government

- Office

GSA Facility – Irving, TX

Size

Location

Owner

Client

The two-story administration building was built by the Department of Homeland Security as a Citizenship and Immigration Services building. This is a regional facility and the executives that work out the office have management responsibility throughout Texas. CCLLC is provided LEED v4 Fundamental and Enhanced Commissioning as well as Whole Building Commissioning requirements for the project.

Commissioning services included design phase review of the OPR and BOD. Construction phase commissioning including Test and Balance verification, issues log tracking and closeout, and development of the final commissioning report. The project achieved LEED Certified Gold.

Government

- Military Base

Rolling Pin Barracks 12000 and 16000 Block

Size

Location

Owner

Client

The project consists of the revitalization/renovation of ten (10) multi-floor barracks buildings—five (5) on the 12000 block and five (5) on the 16000 block. Each building has 3 floors above grade and a Basement Mechanical Room. The purpose of the project is to improve energy efficiency, mitigate mold growth and provide a better living environment for the soldiers that will last for the next 20 years.

Command Commissioning, under the direction of Gensler, evaluated the design, performance, and operation of the Project’s MEP systems from design through construction and acceptance. Specifically, Command Commissioning provided commissioning services to satisfy the requirements of LEED v4, Fundamental and Enhanced Commissioning. The requirements of LEED v4 include: Review the OPR, BOD, and project design, Develop and implement a Cx plan, Confirm incorporation of Cx requirements into the construction documents, Develop construction checklists, Develop a system test procedure, Verify system test execution, Maintain an issues and benefits log throughout the Cx process, Prepare a final Cx process report, Document all findings and recommendations and report directly to the owner throughout the process.

Government

- Office

Pantex ASC

Size

Location

Owner

Client

Designing a state-of-the-art, high-security complex in a remote location with a harsh climate forced the project team to get creative when it came to procuring materials and labor.

The $115-million, 348,000 SQFT Pantex Administrative Support Complex enables the National Nuclear Security Administration to relocate employees from its aging facilities into a modern, energy-efficient facility adjacent to the nearby Pantex Plant.

The construction schedule was tight. And because of the site’s remoteness, materials and labor were distant. These challenges informed the design team’s selection of materials and building systems that could be fabricated of site in controlled environments to eliminate concerns about weather and the site’s distant location.

The end result was a LEED-certified, three-story, precast and glass building that uses flexible floor plates and contains offices to support 1,100 federal and contractor employees.

The complex includes a 365-seat sloped-floor auditorium, a full-service cafeteria, a medical facility for outpatient treatments, a conference center and meeting spaces.

The project was completed on time and under budget.

Government

- Classrooms

City of Houston UAR

Size

Location

Owner

Client

Command Commissioning (CCLLC) developed a Utility Assessment Report (UAR) for several buildings operated by the City of Houston including the Houston Permitting Center, Public Works, and City Hall. CCLLC identified the Houston Permitting Center for implementation of the Continuous Commissioning® (CC®) process and a number of retrofit opportunities at the Public Works building for outside airflow optimization, plant sequence optimization and central air handling unit (AHU) optimization.

Work Performed by individual: Assisted with utility rate reviews, reviewed project baseline energy model calculations. Performed site visits to identify potential opportunities and assisted with the CC® measure identification. After the measure identification, reviewed detailed descriptions and scopes for each measure and assisted with the development of the implementation plan.

Government

- Military Base

NAS Pensacola

Size

Location

Owner

Client

CCLLC supported Pepco Energy Services in the Investment Grade Audit (IGA) for the Naval Air Station–Pensacola (NASP) in Florida. CCLLC combined onsite surveys, sequence reviews, and engineering analysis to identify building requirements, HVAC system deficiencies, Continuous Commissioning® optimization measures, and other energy conservation measures (ECMs) impacting HVAC system performance. Site surveys during the IGA phase are intended to collect information including but not limited to building usage, occupancy requirements, installed equipment configuration and condition, BAS capability, and operational challenges.

The energy savings potential from applying the Continuous Commissioning® process at each building was analyzed using models configured to calculate the annual utility cost savings of modifying the existing mechanical equipment operation. The difference in energy consumption was estimated based on application of conservative performance enhancing control strategies to the as-found control sequences at each building, for each system. This analysis was coordinated with Pepco by utilizing their record of installed equipment and identifying other project ECMs that impact HVAC system performance. This approach ensured consistent use of equipment performance data across the project as well as modeled control strategies based on final HVAC system configuration.

The Continuous Commissioning® process included managing the commissioning issues log, establishing a project-wide trend monitoring program, preparing detailed implementation building submittals to document baseline conditions and recommended sequence strategies and setpoints, overseeing controls vendor responsible for implementing control sequence and hardware modifications, and performing ongoing performance verification. Approximate stats included 975 measures across 29 buildings impacting 15 chilled water plants, 30 heating water plants, 175 AHUs, and 4,000 terminal units.

Government

- Military Base

Cherry Point MCAS

Size

Location

Owner

Client

CCLLC supported Ameresco in the IGA for Cherry Point Marine Corps Air Station (MCAS) in North Carolina. CCLLC combined onsite surveys, sequence reviews, and engineering analysis to identify building requirements, HVAC system deficiencies, Continuous Commissioning® optimization measures, and other ECMs impacting HVAC system performance. Site surveys during the IGA phase are intended to collect information including but not limited to building usage, occupancy requirements, installed equipment configuration and condition, BAS capability, and operational challenges.

Field testing and investigative activities resulted in the generation of a Continuous Commissioning® Issues Log CCxL that includes observed issues and specific recommended corrective actions. The key sensors and devices of the building mechanical systems were tested for accuracy and performance. This targeted effort captured obvious issues preventing successful implementation of the process as well as typical challenges impacting operations at the site. Onsite access to the BAS, as-built controls drawings, site survey information, and project ECM list were used to generate the Continuous Commissioning® Measure Matrix. The targeted optimization measures are divided into five categories: scheduling, air-handlers, terminal units, chilled/condenser water plant, and heating water plant.

The CCM Matrix presented results in three scope categories: modifications to existing systems/sequences, upgrades to controls systems, and coordination with other HVAC related upgrades. The approach to layout the CCMs in one of the three categories of increasing control/system capability will result in more accurate prediction of the total savings estimated. The benefits of this approach include accounting for savings from control sequence modifications based on the cumulative ECMs applied to any system, preventing double-counting of savings.

Government

Austin Information Technology Center

Location

Owner

CCLLC provided electrical commissioning services to include design review of specifications and product data, IR thermography of PDUs and RPPs, tracking of commissioning issues log items and resolution, development of pre-functional checklists, execution of functional performance tests, and a power system study report for ten (10) Power Distribution Units, eight (8) Remote Power Panels and ancillary devices.

Healthcare

- Hospital

JPS MEP Systems Assessment

Size

Location

Owner

Client

Command Commissioning, LLC and DFWCGI performed electrical assessments for 31 facilities, of the John Peter Smith Hospital System for Tarrant County, Texas. This comprised of approximately 500,000 SF of occupied clinical and support facilities. The assessment was performed on a software platform that documented square footage, age and condition of the equipment and approximate cost and date for replacement. A significant sampling of photos were taken to represent the condition and type of equipment encountered.

Healthcare

- Hospital

True Worth Homeless Resource Center

Size

Location

Owner

Client

TrueWorth Homeless Resource Center and Clinic opened its doors in December of 2016. TrueWorth serves individuals and families in Fort Worth who find themselves homeless. They offer day shelter, supportive services and resources, and access to partner agencies. TrueWorth and the new facility are funded by the Fort Worth Foundation, whose mission is to support local organizations working to feed the hungry and improve the lives of homeless individuals and families in the area.

The facility was designed by HKS and DFW Consulting Group provided the MEP engineering. The facility is about 40,000 SQFT and includes a restroom and showers, laundry facilities, mailing address, telephones, computers, temporary storage, a kitchen, and medical and dental clinics. TrueWorth works to link guests with healthcare, employment, education, mental health and substance abuse treatment, critical documents, and more.

Hospitality

- Retail

Entertainment District – Dallas, Texas

Size

Location

CCLLC provided technical commissioning, infrared testing, and specialty system verification services. This included manpower and expertise to perform commissioning, testing, and verification across 19 projects associated with this development: Premise Medical Center, 1T, Restaurant, Lobby, Cafeteria, Food Hall, CHW Heat Exchanger, UPS Central Security, 2T Auditorium, Experience Store, 3T, Beer Garden, 4T, HHW Heat Exchanger, 5T, Plaza Fountains, Plaza, Smart Parking. There were multiple food court vendors and a beer garden. Multiple vent hoods were installed, multiple freezer and refrigerators as well as a pollution inspection.

Hospitality

- Multi-Purpose

American Airlines Hospitality Complex

Size

Location

Owner

Client

528,000 SF tower with another 107,000 SF of below-grade parking. The complex will house 600 guestrooms, an indoor swimming pool, a clinic, fitness area, restaurant, cafeteria, and laundry area to meet the needs of airline staff and travelers. CCLLC is provided LEED v4 Fundamental and Enhanced Commissioning as well as Whole Building Commissioning requirements for the project.

Hospitality

- Hotel

Sheraton Georgetown

Size

Location

The Sheraton Hotel and Conference Center is a new 225-room, seven-story hotel that includes a conference center/ballroom, meeting rooms, swimming pool, gift shop, business center, on-site laundry and a 4-story, 340 space parking garage. The Hotel pursued LEED certification. CCLLC provided all of the necessary related commissioning services for the effort.

Technology

- Mission Critical/Data Center

Data Center Building Automation System Replacement

Size

Location

Owner

Client

CCLLC was tasked with commissioning a complete systems BAS upgrade of mission critical data center facilities. The controls systems swapped out the existing Johnson Controls to a Siemens controls system with security criteria necessary for federal compliance. The controls system upgrade included power generation systems, central plant chillers and cooling towers, Air-Handling Units, CRAHs, terminal units, and all of the ancillary support equipment including sensors, control devices, and pumps to support their operation.

This project included multiple phases through conceptual design to construction and commissioning requiring coordination of various team members across the state and nation to meet the scheduling deadlines and manpower requirements.